AQUAM Solutions offers a full range of technical treatment solutions tailored to the needs of its customers, from diagnosis to the implementation and operation of the solution.

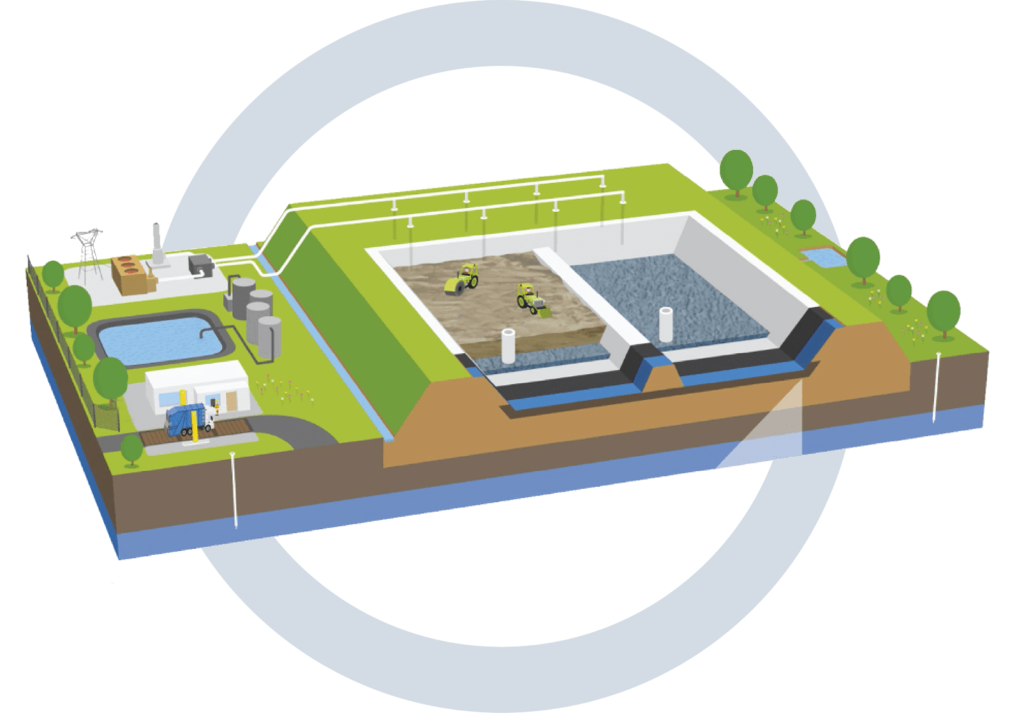

For landfill sites, AQUAM Solutions offers a comprehensive solution for leachate treatment and biogas recovery. It works with its customers to minimise interfaces, and often adapts solutions as sites and waste composition change.

- Definition of input data

- Estimation of leachate production and analysis of leachate quality - Analysis of site constraints

- Analysis of operating constraints

- Analysis of regulatory constraints

- Design of leachate collection networks

- Optimisation of leachate production

- Definition and validation of the leachate/industrial water treatment process

- Sizing of the leachate/industrial water treatment process

- Production of technical documents (PID, Equipment plans, GC guide plans, Equipment technical specifications....

- Launching consultations and assisting customers with the internal purchasing process.

- Setting up subcontracting agreements.

- Project management (planning, financial and contractual monitoring).

- Installation of equipment.

- Commissioning

- Operator training.

- Acceptance of the installation.

- Operation or assistance with operation of the unit.

- Setting up an operating monitoring file.

- Monitoring the unit's process parameters.

- Monitoring the unit's KPIs.

- Implement and monitor the improvement plan.

- Implementation and monitoring of the maintenance plan.

- Assistance with operation or operation of the unit on behalf of the customer.

- Definition of input data.

- Estimation of biogas source and optimum quantity to be recovered,

- Analysis of site constraints.

- Analysis of operating constraints.

- Analysis of regulatory constraints.

- Estimation of investment and operating costs.

- Validation of the business plan and project profitability

- Defining and validating the recovery process

- Set up pilot tests if necessary.

- Sizing of the recovery process

- Production of technical documents (PID, Equipment plans,

GC Guide drawings, technical specifications for equipment.

- Launch consultations and support customers

in the internal purchasing process.

- Setting up subcontracting agreements.

- Project management (planning, financial and contractual monitoring).

- Installation of equipment.

- Commissioning.

- Operator training.

- Acceptance of the installation.

- Setting up an operating monitoring file.

- Monitoring the unit's process parameters.

- Monitoring the unit's KPIs.

- Implement and monitor the improvement plan.

- Implementation and monitoring of the maintenance plan.

- Assistance with operation or operation of the unit on behalf of the customer.